TAPERED ROLLER BEARING (TRBs) stand as a testament to precision engineering. Offering a sophisticated solution for handling both radial and axial loads in various mechanical applications. In this exploration, we examine the design principles, advantages and diverse applications of tapered roller bearings, highlighting their important role in enhancing the performance and reliability of rotating machinery.

Principles of TAPERED ROLLER BEARING Design:

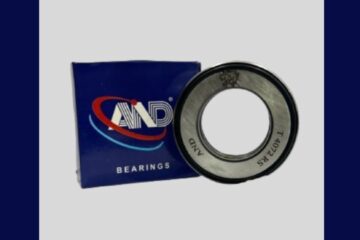

Taper roller bearings are aptly named for their cone-shaped rollers and raceways. which enables them to handle both radial and axial loads simultaneously. The design features tapered raceways with inner and outer rings as well as tapered rollers. This configuration allows for efficient load distribution, reduced friction, and increased axial and radial stiffness are particularly adept at accommodating high radial and axial forces in both directions

Advantages of Taper Roller Bearings:

Versatility: Taper roller bearings are versatile and suitable for a wide range of applications. This includes automotive, industrial machinery and heavy equipment.

High load capacity: TRBs are designed to handle both radial and axial loads, making them ideal for applications

Where forces act in multiple directions.

Accuracy and Stiffness: The tapered design provides precision in load distribution, improving stiffness and reducing deflection under heavy loads.

Longevity:

The taper roller bearing configuration allows for weight distribution, reducing stress on individual components and contributing to increased bearing life.

In All Industry:

Tapered Roller Bearings (TRBs) are widely used in various industries due to their ability to withstand heavy loads and provide precise motion. Automotive Append cations, industries commonly use them in wheel bearings, transmission, and differential assemblies. In industrial machinery, gearboxes, conveyors, and mining equipment employ TRBs The aerospace sector also benefits from their versatility, ensuring reliable performance in critical components such as aircraft landing gear

Applications:

The evolving engineering landscape has given rise to modern variations of tapered roller bearings. Including double row and four row configuration. Double-row tapered roller bearings increase load-carrying capacity, while four-row tapered roller bearings are designed for heavy-duty applications, such as rolling mills and large gearboxes.

0 Comments