SBS BEARINGS

NEEDLE ROLLER BEARINGS

Needle roller bearings are a type of rolling element bearing designed to handle radial loads in a compact and lightweight structure.

welcome to

SBS BEARINGS

The fundamental design of needle roller bearings consists of cylindrical rollers with a much smaller diameter compared to their length. This unique geometry allows needle roller bearings to achieve a high load-carrying capacity within a small envelope

NEEDLE ROLLER BEARINGS

The rollers are guided by a cage, usually made of steel or synthetic materials, which prevents direct contact between adjacent rollers and ensures proper spacing.

discover more

0

+

Happy Customers

0

%

Service Guarante

0

+

Cleaners

0

+

Cleans Completed

SBS BEARINGS

Related Product

These bearings consist of an inner and outer ring, with a set of steel balls positioned between them

Charlotte Olivia

WordPress Dev.

Jane Doe

WordPress Dev.

Cindi Parker

WordPress Dev.

Jhon Doe

WordPress Dev.

K. K. Dokania

WordPress Dev.

A small river named Duden flows by their place and supplies it with the necessary regelialia. It is a paradisematic .

Amelia Ava

WordPress Dev.

A small river named Duden flows by their place and supplies it with the necessary regelialia. It is a paradisematic .

Lucy Evelyn

WordPress Dev.

A small river named Duden flows by their place and supplies it with the necessary regelialia. It is a paradisematic .

SBS BEARINS

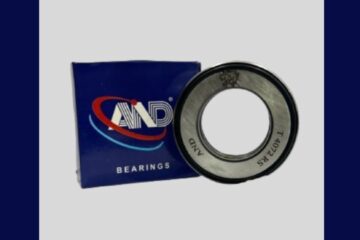

Our Brands

These bearings are widely used in various industrial applications where space is limited, and high radial load-carrying capacity is essential.

KOYO

KOYO (Guangyang Seiko Co., Ltd.) was founded in 1921. It is a Japanese company engaged in research and development of comprehensive functional products, with 6557 employees

TIMKEN

TIMKEN is the world’s leading manufacturer of high-quality bearings, alloy steel and related parts and accessories. No matter where in the world, as long as there is equipment

0 Comments