Introduction:

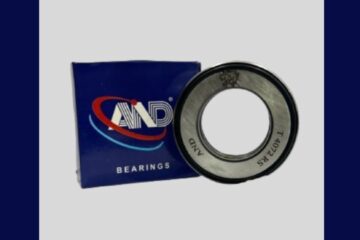

Chrome Steel Bearings ,In the realm of precision engineering, emerge as stalwarts, embodying the synergy between metallurgical excellence and mechanical precision. Renowned for their durability, corrosion resistance, and superior load-carrying capabilities, these bearings play a pivotal role in a diverse range of applications. In this exploration, we unravel the metallurgical intricacies, design principles, and versatile applications that make Chrome Steel Bearings an indispensable force in the world of rotating machinery.

Metallurgical Mastery:

At the core of Chrome Steel Bearings lies the choice of materials, specifically alloyed chrome steel. This metallurgical masterpiece combines iron, chromium, and other elements, resulting in a steel alloy celebrated for its exceptional strength, hardness, and resistance to corrosion. The high carbon content contributes to the hardness, while chromium enhances corrosion resistance, making Chrome Steel Bearing adept at withstanding challenging operating conditions.

Robust Design Principles:

Chrome Steel Bearing, much like their steel counterparts, exhibit a robust and well-established design. Consisting of an inner and outer ring, a set of steel balls. These bearings facilitate smooth rolling motion and minimize friction. The precision manufacturing of the steel balls and raceways ensures consistent and reliable performance under various loads and speeds.

Chrome Steel Bearings Corrosion Resistance and Durability:

The chromium content in Chrome Steel Bearing imparts a protective oxide layer on the surface. Enhancing resistance to corrosion and wear. This makes them particularly suitable for applications where exposure to harsh environments. Moisture or chemicals is prevalent. The durability of Chrome Steel Bearing contributes to their extended lifespan. Reliability in critical machinery.

Chrome Steel Bearings Versatile Applications Across Industries:

Chrome Steel Bearing find applications across a broad spectrum of industries, from automotive and aerospace to industrial machinery. In automotive systems, they are integral to wheel hubs, transmissions, and engine components, providing efficient power transmission and enduring performance. Aerospace applications benefit from the combination of strength and reduced weight, contributing to the overall efficiency of aircraft systems.

0 Comments