Introduction:

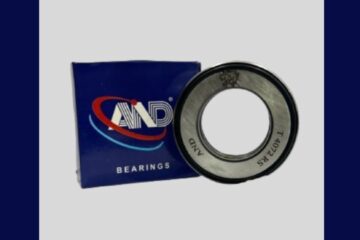

Copper Cage Bearings, In the intricate landscape of precision engineering. Bearings with copper cages stand out as exemplars of metallurgical innovation. The cage, a critical component within the bearing assembly. Is traditionally crafted from various materials, and copper emerges as a distinctive choice for its unique properties. In this exploration, we delve into the realm of copper cage bearings, shedding light on the advantages, applications, and the metallurgical intricacies that contribute to their prominence in the world of rotating machinery.

Copper Cage Bearings Metallurgical Advantages:

The choice of copper as a material for bearing cages is rooted in its exceptional combination of properties. Copper exhibits superior thermal conductivity, ensuring efficient heat dissipation within the bearing assembly. This property is particularly crucial in high-speed applications where heat generation is a concern. Additionally, copper’s excellent corrosion resistance adds a layer of durability, contributing to extended bearing life and reliability in diverse operating conditions.

Copper Cage Bearings Enhanced Lubrication and Reduced Friction:

Copper cage bearing facilitate enhanced lubrication due to their ability to act as a reservoir for lubricating oils or greases. The cage’s design allows for optimal distribution of lubricants, ensuring a consistent and reliable supply to the rolling elements. This results in reduced friction, minimizing wear and heat generation, and ultimately contributing to the overall efficiency and longevity of the bearing.

Applications Across Industries:

Copper cage bearing find applications across a spectrum of industries, ranging from automotive and aerospace to industrial machinery. In automotive applications, these bearings are commonly employed in transmissions. Wheel hubs, where high-speed operation and efficient heat dissipation are critical. In aerospace, the lightweight and thermally conductive properties of copper make it a suitable choice for bearing cages in aircraft engines. Moreover, industrial machinery, such as electric motors and gearboxes, benefits from the enhanced performance and durability offered by copper cage bearings.

Metallurgical Precision in Manufacturing:

Crafting copper cage bearings requires precision in metallurgy. Manufacturers meticulously design and engineer these cages to meet specific load, speed, and lubrication requirements. The manufacturing process involves shaping, forming, and sometimes heat treatments to ensure the final cage meets the demanding standards of modern machinery.

0 Comments