GEAR BOXES Introduction:

GEAR BOXES bearings play a crucial role in the efficient and smooth operation of a gearbox. Which is a vital component in various machinery and vehicles. These bearings are specifically designed to support the rotational movement of gears within the gearbox. Ensuring proper alignment and reducing friction between moving parts.

One of the primary functions of gear boxes bearings is to support the weight of the gears and shafts. Allowing them to rotate freely while maintaining their proper positions. This is essential for the transmission of power from the input shaft to the output shaft, enabling the gearbox to fulfill its role in speed reduction, torque multiplication, or direction change, depending on the application.

GEAR BOXES Mission

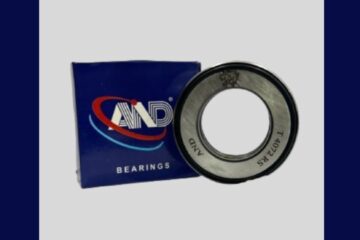

The selection of suitable gearbox bearings depends on several factors, including the gearbox’s design, load capacity, rotational speed, and the type of gears involved. Common types of bearings used in gearboxes include ball bearings, roller bearings, and needle bearings. Each type has its advantages and is chosen based on the specific requirements of the gearbox.

Ball bearings are widely used in gearboxes due to their ability to handle both radial and axial loads. They consist of small metal balls housed in a circular race, providing smooth rotation and low friction. Roller bearings, on the other hand, use cylindrical rollers to distribute loads evenly, making them suitable for heavy-duty applications where high load capacities are required. Needle bearings are compact and have a high load-carrying capacity, making them suitable for applications with limited space.

Proper lubrication is critical for gearbox bearings to reduce friction, dissipate heat, and prevent premature wear. Lubricants create a protective film between the bearing surfaces, enhancing their longevity and overall performance. Regular maintenance, including lubricant checks and replacements, is essential to ensure the optimal functioning of gearbox bearings.

In conclusion, gearbox bearings are integral components that facilitate the smooth and efficient operation of gearboxes in various applications. Their ability to support loads, reduce friction, and withstand rotational forces contributes to the overall reliability and performance of machinery and vehicles. Proper selection, installation, and maintenance of gearbox bearings are essential to extend their lifespan and ensure the optimal functioning of the entire gearbox system.

0 Comments