Introduction:

In the intricate web of industrial machinery, Industrial Bearings emerge as linchpins, meticulously engineered to withstand the challenges of diverse applications. These versatile components play a pivotal role in countless industries, facilitating smooth rotation, minimizing friction, and ensuring the reliability of critical machinery. In this exploration, we uncover the fundamental characteristics, diverse applications, and overarching significance of industrial bearings in the multifaceted landscape of modern manufacturing.

Versatility Across Industries:

Industrial Bearing find applications in a vast array of industries, ranging from automotive and aerospace to energy, construction, and beyond. Their versatility is evident in their ability to adapt to the unique demands of each sector, contributing to the efficiency, reliability, and precision of diverse machinery.

Industrial Bearings Design Principles:

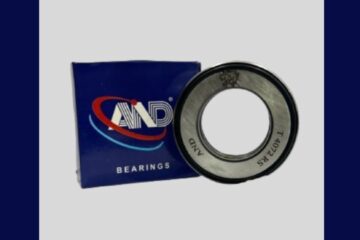

The design of Industrial Bearing is rooted in precision engineering. With a focus on minimizing friction and maximizing load-carrying capacity. Bearings generally consist of an inner and outer ring, rolling elements (balls or rollers), and a cage. To maintain proper spacing between the rolling elements. This well-thought-out design ensures smooth rotation and efficient transmission of loads.

Industrial Bearings Diverse Types for Varied Applications:

The diverse nature of industrial applications has led to the development of various types of bearings. Each tailored to specific needs. Ball bearings, roller bearings, needle bearings, and thrust bearings are just a few examples. The choice of bearing type depends on factors such as load capacity, speed. And the nature of the application.

Precision and Efficiency:

Precision is a hallmark of Industrial Bearings, contributing to the overall efficiency of machinery. Whether in precision instruments or heavy-duty manufacturing equipment, the ability of bearings to maintain accurate alignment and reduce friction directly impacts the performance and lifespan of the machinery.

Specialized Bearings for Unique Challenges:

Certain industries pose unique challenges that require specialized bearing solutions. High-temperature environments, corrosive conditions, or high-speed applications may necessitate bearings crafted from specific materials or featuring advanced designs. Manufacturers continually innovate to address these challenges, resulting in bearings that can thrive in diverse and demanding industrial settings.

0 Comments