Mills Bearings Introduction:

Within the heart of industrial operations, Mills Bearing serve as the unsung guardians of rotating machinery, facilitating the continuous flow of production. These specialized bearings play a pivotal role in various types of mills, ranging from paper mills to steel mills, ensuring the reliability, efficiency, and longevity of critical equipment. In this exploration, we’ll delve into the unique characteristics, applications, and importance of mill bearings in the dynamic landscape of industrial processing.

Heavy-Duty Design for Industrial Environments:

Mills Bearing are engineered with a heavy-duty design. To withstand the demanding conditions prevalent in industrial mills. These conditions include high loads, varying speeds, and often harsh environmental factors. The robust construction of mill bearings ensures resilience under the challenging. Operational circumstances commonly encountered in industrial settings.

Mills Bearings Diverse Applications in Different Mills:

Mill Bearing find applications in a diverse array of mills, each with unique processing requirements. In steel mills, these bearings support the heavy loads and extreme temperatures encountered in rolling and processing metals. In paper mills, they contribute to the precision needed for continuous paper production. Whether in textile mills, sawmills, or other industrial facilities, mill bearings are integral components that facilitate the smooth rotation of machinery.

Specialized Designs for Specific Mill Processes:

Different types of mills demand specialized designs for bearings to accommodate their specific processes. For example, rolling mill bearings are engineered to handle heavy axial and radial loads generated during metal rolling operations. The design may incorporate features such as tapered roller bearing. Cylindrical roller bearings, or spherical roller bearings, depending on the specific requirements of the mill process.

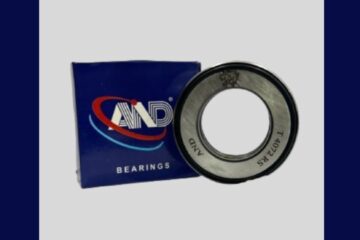

Sealed Bearings for Contamination Control:

Mills Bearing often feature sealed designs to prevent the intrusion of contaminants like dust, dirt, and moisture. Seals play a crucial role in preserving the integrity of the bearing assembly, reducing the risk of wear, and extending the maintenance intervals. This is particularly important in industrial environments where cleanliness and reliability are paramount.

0 Comments