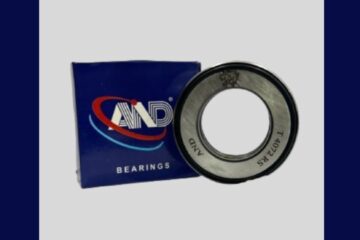

Introduction: Thrust Bearing

Thrust bearing, a fundamental component in mechanical engineering, are designed to handle axial loads. Providing stability and efficient rotation in various machinery. We delve into the world of thrust bearings. Uncovering their design principles, applications. The crucial role they play in optimizing the performance of rotating systems.

Design Principles:

Engineered primarily to handle axial loads, thrust bearings manage forces applied parallel to the axis of rotation. The design usually incorporates flat surfaces or rollers arranged to efficiently transmit these axial loads. Thrust bearings come in various types, including ball thrust bearings, roller thrust bearings, and fluid thrust bearings. The selection of design depends on factors such as load capacity, speed, and specific application requirements.

0 Comments