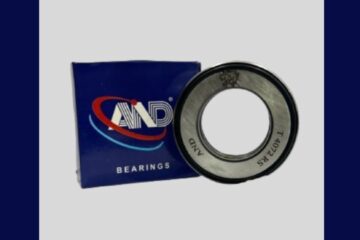

Oil Seal Bearings

Oil Seal Bearings ,In the intricate dance of machinery, coordination between bearings and oil seals is paramount. This article explores the symbiotic relationship, exploring how these components work hand in hand to ensure optimal performance, longevity, and minimal maintenance in a variety of industrial applications.

Understanding bearings in the context of oil seals:

Bearings act as a mechanical backbone, enabling rotational or linear motion in machinery. Discover how different types of bearings, such as ball bearings or roller bearings, complement the functions of oil seals to prevent friction, support loads, and facilitate smooth operation.

Oil Seal Bearings: Lubricants Integrity Protectors:

Unveil the role of oil seals in the protection of machinery. These essential ingredients act as a preservative, preventing the escape of lubricants and the ingress of contaminants. Explore the different types of oil seals and their important role in maintaining a sealed, lubricated environment inside bearings.

Real world applications:

From automotive engines to industrial gearboxes, witness how the combination of bearings and oil seals ensure the integrity of critical machinery components. Real-world examples demonstrate the importance of this dynamic duo in increasing performance and reducing attrition.

Choosing the right bearings and oil seals:

Navigate the selection process by understanding the compatibility of bearings and oil seals. Factors such as material compatibility, temperature resistance, and load bearing capacity come into play. Learn how proper selection contributes to a harmonious and sustainable machinery system.

Care Methods for Longevity:

Discover the best practices for maintaining the integrity of oil seals and bearings. From regular inspections to proper lubrication, this section offers insight into precautions that can both extend the life of components, and reduce the need for costly repairs.

Result:

In the great symphony of machinery, the cooperation between bearings and oil seals is a chord of health and safety. From their individual roles to their seamless integration, understanding how these components work together is essential for engineers, maintenance professionals, and anyone interested in the inner workings of machines. As we conclude, the harmonious partnership of bearings and oil seals remains a cornerstone in the world of mechanical engineering, ensuring the smooth and reliable operation of countless devices and systems.

0 Comments