SBS BEARINGS

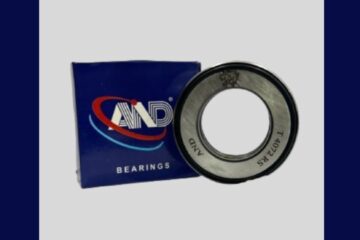

THRUST BALL BEARINGS

Thrust ball bearings play a pivotal role in the field of mechanical engineering, enabling the smooth operation of machinery that involves axial loads.

welcome to

SBS BEARINGS

One of the key advantages of thrust ball bearings lies in their ability to support heavy axial loads while maintaining low rotational friction.

THRUST BALL BEARINGS

At their core, thrust ball bearings consist of two relatively flat rings – the housing washer and the shaft washer – with ball bearings positioned between them. The design facilitates the transfer of axial loads along the axis of rotation

discover more

0

+

Happy Customers

0

%

Service Guarante

0

+

Cleaners

0

+

Cleans Completed

SBS BEARINGS

Related Product

These specialized bearings are designed to handle thrust or axial forces, allowing for efficient transmission of power and motion in various applications.

Charlotte Olivia

WordPress Dev.

Jane Doe

WordPress Dev.

Cindi Parker

WordPress Dev.

Jhon Doe

WordPress Dev.

K. K. Dokania

WordPress Dev.

A small river named Duden flows by their place and supplies it with the necessary regelialia. It is a paradisematic .

Amelia Ava

WordPress Dev.

A small river named Duden flows by their place and supplies it with the necessary regelialia. It is a paradisematic .

Lucy Evelyn

WordPress Dev.

A small river named Duden flows by their place and supplies it with the necessary regelialia. It is a paradisematic .

SBS BEARINS

Our Brands

A small river named Duden flows by their place and supplies it with the necessary regelialia. It is a paradise

KOYO

KOYO (Guangyang Seiko Co., Ltd.) was founded in 1921. It is a Japanese company engaged in research and development of comprehensive functional products, with 6557 employees

TIMKEN

TIMKEN is the world’s leading manufacturer of high-quality bearings, alloy steel and related parts and accessories. No matter where in the world, as long as there is equipment

0 Comments