Introduction:

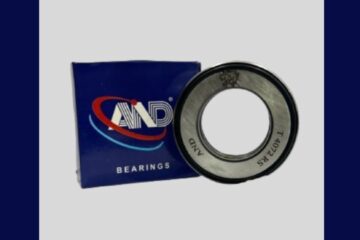

Truck Bearings ,In the robust world of heavy-duty transportation, Truck Bearings serve as unsung heroes, bearing the weight and ensuring the smooth rotation of wheels that power the wheels of industry. These specialized bearings play a critical role in the performance, reliability, and safety of trucks, buses, and other heavy vehicles. In this exploration, we’ll delve into the unique design features, applications, and importance of truck bearings in the demanding realm of commercial transportation.

Truck Bearings Design for Heavy Loads:

Truck Bearing are meticulously designed to withstand the immense loads and dynamic forces encountered by heavy vehicles. Whether in the wheel hubs, axles, or transmissions. These bearings are engineered to manage substantial radial and axial loads. While enduring the challenges of varied terrains and operational conditions.

Truck Bearings Diversity of Applications:

The applications of Truck Bearing extend across the entire spectrum of heavy-duty vehicles. From long-haul trucks and buses to construction vehicles and off-road machinery, these bearings are integral components that ensure the reliability and efficiency of the vehicle’s rolling elements. They contribute to the seamless operation of wheels, axles, and other rotating parts critical to the transportation industry.

Truck Bearings Sealed for Protection:

Given the exposure of heavy vehicles to harsh environmental conditions. Truck Bearing often feature sealed designs. Seals act as protective barriers guarding against contaminants like dust, dirt, and moisture. This not only ensures the longevity of the bearings. But also reduces the risk of premature wear and damage, crucial for maintaining the safety and reliability of the vehicle.

Tapered Roller Bearings for Efficiency:

Tapered Roller Bearings are commonly employed in truck applications due to their ability to handle both radial and axial loads efficiently. The tapered design allows for precise load distribution, reducing friction and contributing to the overall fuel efficiency of the vehicle. This is particularly crucial in the transportation industry where fuel costs and operational efficiency are paramount.

Critical Role in Safety:

The reliability and proper functioning of Truck Bearing play a direct role in ensuring the safety of heavy vehicles. A failure in the bearing system can lead to catastrophic consequences, underscoring the importance of high-quality, durable bearings in the design and maintenance of trucks and other commercial vehicles.

Maintenance Considerations:

Regular maintenance of Truck Bearing is imperative to guarantee their optimal performance and prevent unexpected failures. Lubrication intervals, inspection for signs of wear or damage, and adherence to manufacturer-recommended guidelines contribute to the longevity and reliability of these bearings, reducing downtime and maintenance costs for truck operators.

0 Comments